Key Takeaways

- Triple screw vessels, equipped with three engines, provide superior thrust, better acceleration, and enhanced maneuverability.

- With consistent performance in various marine conditions, triple screw vessels minimize downtime in critical operations like rescue missions, offshore work, and heavy-duty towing.

- The distribution of power across three engines reduces engine strain, leading to better fuel efficiency and lower operational costs over time.

- From commercial fishing to tugboats and offshore operations, triple screw vessels deliver real-world benefits, including high power, precise control, and the ability to handle demanding tasks efficiently.

- Laborde Products offers extensive expertise, reliable marine power solutions, and top-notch customer support.

Without reliable and powerful equipment, your marine operations won’t meet your high standards. Triple screw vessels, with their namesake three engines, are the top choice for delivering exceptional power and performance on the water. In this blog, we’ll find out why and highlight how Laborde Products connects the marine industry to this triple threat on the water.

Benefits of Triple Screw Vessels

Triple screw vessels are the standout choice for marine operations. From enhanced power and performance to unmatched reliability and fuel efficiency, these vessels are awash in positive impacts for your marine operations.

Power and Performance

Triple screw vessels are built for power. With three engines, there’s significantly more thrust compared to single or twin screw vessels. That’s better acceleration and a noteworthy ability to maintain higher speeds even when carrying heavy loads. The increased power also translates to superior maneuverability for precise control in tight or challenging conditions. Rocky waters or busy ports—you’ll get the job done.

Reliability

Triple screw vessels excel with consistent performance in various marine conditions, from calm seas to rough weather. This reliability is crucial in scenarios where failure is not an option, such as during rescue missions, offshore operations, or towing heavy loads. The redundancy of having three engines means that even if one fails, the vessel can still operate effectively, reducing the risk of downtime and powering continuous operation.

Fuel Efficiency

And with better distribution of power across three engines, triple screw vessels can achieve optimal propulsion with less strain on each engine. This efficiency not only reduces fuel consumption, but also lowers operational costs over time. The savings in fuel expenses make triple screw vessels a cost-effective choice for long-term marine operations, allowing businesses to maximize their budget without compromising on performance or reliability.

Practical Applications of Triple Screw Vessels

Triple screw vessels aren't just about power and efficiency on paper—they deliver real-world benefits in various marine industries. Let's dive into how these vessels make a difference in commercial fishing, tugboats, workboats, and offshore operations.

Commercial Fishing

In the commercial fishing industry, reliability and power are key. Triple screw vessels flex the muscle needed to haul in large catches and handle heavy nets without breaking a sweat. Their benefits include:

- Superior maneuverability for precise navigation in crowded fishing areas

- Increased power to manage heavy loads and long hours on the water

- Dependable performance that won’t fail your crew

Tugboats and Workboats

Tugboats and other workboats need to be tough and versatile. Triple screw vessels offer:

- High power and control for towing large ships and navigating tight spaces

- Extra thrust from three engines for better handling of heavy loads

- Enhanced stability to tackle demanding tasks like pushing barges or pulling disabled vessels

Offshore Operations

In offshore operations, such as oil and gas exploration, the stakes are high. Triple screw vessels are vital for these missions, providing:

- Reliability and strength in harsh marine environments

- Stability and power for transporting equipment and personnel to offshore rigs

- Enhanced fuel efficiency, helping to reduce operational costs for long-term projects

Triple screw vessels prove their worth across various applications, making them a valuable asset for any marine operation looking for dependable power and performance.

How To Choose The Right Triple Screw Propulsion System

Selecting the right triple screw propulsion system for your vessel involves weighing several factors. These considerations will help you make an informed choice to match your vessel's operational demands.

Bollard Pull

Bollard pull measures the pulling force a vessel's engines generate when pulling against a stationary object. High bollard pull is key for towing and pushing tasks. Triple screw systems typically have greater bollard pull than twin-screw systems, making them ideal for power-heavy operations.

Vessel Size

Your vessel's size directly impacts the choice of propulsion system. Larger vessels benefit more from triple screw systems due to their power and speed requirements. When choosing vessel size, think about its purpose and the needed bollard pull. For example, tugboats and workboats that require significant bollard pull need larger vessels with more powerful engines.

Engine Emissions

Triple screw systems can provide necessary power while adhering to emission standards. Engines like the Tier 3 Mitsubishi S6R2 are designed to meet these regulations, making them a good choice for any modern-day operations. Meeting compliance with emission standards helps avoid regulatory issues while maintaining your marine practices.

Fuel Efficiency

Triple screw systems generally have better fuel efficiency than twin-screw systems, lowering operating costs. Opting for systems with larger displacement rates and lower compression ratios can further improve fuel efficiency by reducing engine stress. This results in more economical operations over the vessel’s lifetime.

Engine Reliability

Triple screw systems, like the Mitsubishi S6R2, are known for their durability and consistent performance under high stress. These engines can handle demanding conditions and long operational periods, making them a dependable choice for various commercial marine vessels.

Case Study: Mitsubishi S6R2-Y3MPTAW Engine in Action with Triple Screw Propulsion

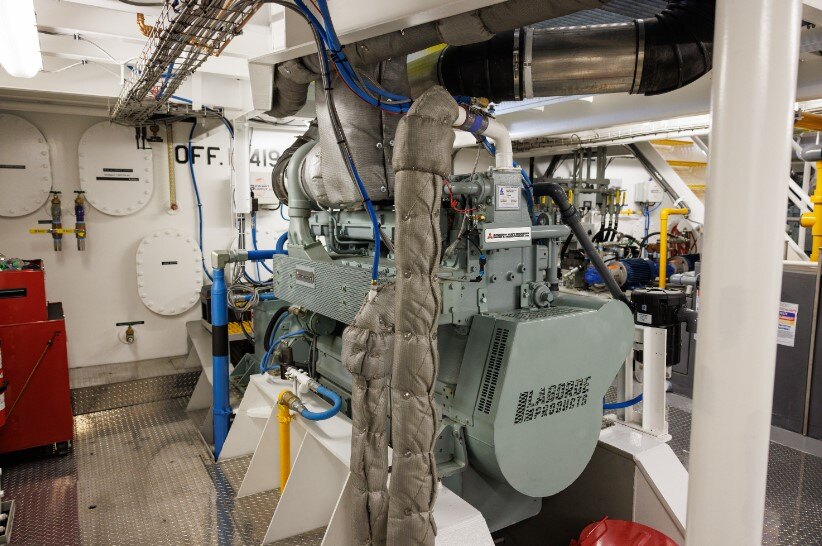

When it comes to selecting an engine for large-scale boats, the Mitsubishi S6R2-Y3MPTAW has proven its worth. But how does this engine perform in real-world conditions, especially when integrated into a triple screw propulsion system? Donjon Marine, in partnership with Laborde Products, put it to the test with their new triple screw tugboat.

Putting the Engine to Work

Donjon Marine, a leader in marine salvage, towing, dredging, and related services, chose the Mitsubishi S6R2-Y3MPTAW engine for their new triple screw tug. More than merely about specs, Donjon Marine’s decision was about finding an engine that could handle the daily demands of their operations and leverage the advantages of triple screw propulsion. Laborde Products provided the expertise and support needed to integrate this engine seamlessly.

Meeting Propulsion Needs

Founded in 1964, Donjon Marine has a long history in the marine industry. They needed an engine that could meet their current and future needs. Capt. William J. Sullivan, manager of regulatory compliance and vessel repair, highlighted the importance of considering various factors such as bollard pull, environmental regulations, fuel efficiency, and engine reliability.

Key Considerations for Donjon:

- Bollard Pull: Ensuring the triple screw system could generate enough power for towing and pushing tasks.

- Environmental Compliance: Meeting stringent emission standards.

- Fuel Efficiency: Reducing operational costs with efficient fuel consumption.

- Reliability: Choosing an engine known for durability and consistent performance.

After evaluating these factors, Donjon decided the Mitsubishi S6R2-Y3MPTAW, supplied by Laborde Products, was the best fit. This engine's larger displacement rates, low compression ratios, and minimal stress on components made it ideal for their needs, especially when paired with a triple screw propulsion system.

Performance and Feedback

Donjon's tug captains and engineers have praised the Mitsubishi engine's performance in their triple screw setup. They noted its reliability and power, which has made a significant difference in their daily operations. The feedback confirmed that the S6R2-Y3MPTAW engine was a "perfect fit," providing the necessary horsepower while maintaining a small footprint and manageable weight.

Why Choose Laborde Products for Your Triple Screw Vessel Needs?

As demonstrated by Donjon Marine’s experience, Laborde Products stands out as the top choice for your triple screw vessel needs. With extensive expertise in providing reliable marine power solutions, we offer the best advice and products tailored to your vessel. Our commitment to customer support means you have assistance every step of the way, from initial consultation to ongoing maintenance.