Replacing a trusted engine like the CAT C18 with a Mitsubishi S6R-Y3 might seem daunting at first, but when you dive deeper into the repower process, the benefits far outweigh the initial hesitation. Here are key takeaways to consider:

Key Takeaways:

- Historical Context: The CAT C18's design origins and EPA Tier 2 compliance.

- Engine Dimensions: Necessary vessel adjustments for accommodating the increased size of the Tier 3 Mitsubishi S6R.

- Bellhousing and Gear Ratios: Ensuring compatibility and performance optimization during the repower.

- Engine and Parts Availability: Comparing the availability and lifespan of the CAT C18 versus the Mitsubishi S6R.

- Best Use Applications: Evaluating the suitability of the C18 and S6R for different marine applications.

Navigating Regulatory Changes and Performance Challenges in Repowering the CAT C18

Recognizing the historical context and regulatory changes affecting engine performance is crucial when considering a repower. The CAT C18, part of Caterpillar Marine's renowned C-series lineup, was originally designed for pleasure craft applications before transitioning to the commercial sector.

While this engine has earned a reputation for reliability, particularly in lighter-duty applications, its design origins influence its performance in more demanding environments. The C18 replaced the highly popular 3400 series engines, such as the 3408 and 3412, and the C32 even stepped up to the horsepower range of the 3508, reaching up to 1,000 horsepower. Although these mechanical Tier One and Tier Zero engines were favored and continue to be appreciated, they have been phased out in favor of the electronic C-series engines.

The Caterpillar C-series engines were initially high-performance pleasure craft engines, and their design may not be ideally suited for heavy-duty applications such as tugboats or pushboats. High lifecycle costs, driven by the need for specialized dealer services, high electronic component costs, and parts scarcity, make them less economical for heavy-duty commercial use.

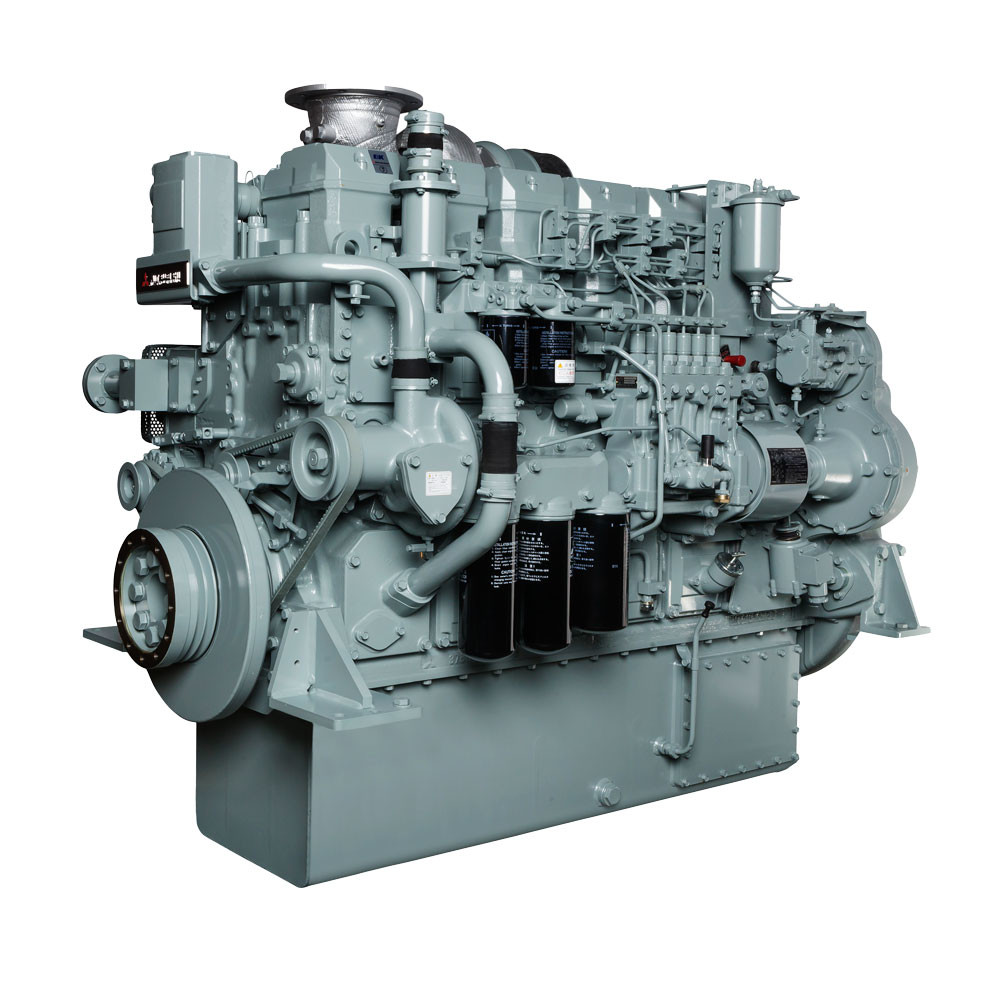

With the introduction of EPA Tier 2 regulations, which mandated significant reductions in emissions for off-road diesel engines, manufacturers had to innovate. While the C18 meets these standards, the Mitsubishi was engineered with these regulations in mind from the outset. This design foresight results in an engine that not only complies with emission requirements but is also optimized for durability and long-term performance under challenging conditions.

Addressing Exhaust Piping Adjustments for the Mitsubishi S6R-Y3

A key consideration during the repower process is the difference in physical dimensions between the C18 and the Tier 3 S6R, especially in terms of height. The Mitsubishi engine is about 12 inches taller, which can impact the existing exhaust piping layout in vessels with limited vertical space.

In many vessels, especially those with tight engine rooms, the added height of the S6R-Y3 can interfere with existing exhaust piping layouts. Some vessels have a second deck or structural components that encroach on the engine room’s vertical space. The taller Mitsubishi engine might necessitate rerouting or enlarging the exhaust piping; however, this is a straightforward modification that can be easily managed with proper planning. Typically, the C18 uses 8-inch exhaust and 5- to 6-inch air inlet piping, while the S6R, with its larger 24.5-liter displacement compared to Caterpillar's 18 liters, requires 10-inch exhaust and larger air inlet piping.

Many operators find that rerouting the exhaust piping or making slight adjustments to the engine room structure is a small price to pay for the significant performance and durability enhancements that come with the Mitsubishi Marine Engine. The benefits in reliability and cost savings far outweigh the initial adjustments, making this repower a smart choice for those looking to enhance their vessel's engine performance.

Ensuring Bellhousing Compatibility for a Seamless Integration with Mitsubishi S6R-Y3

Another consideration for a successful repower is bellhousing compatibility. The CAT C18 can be ordered with either a No. 1 or No. 0 bellhousing, depending on the application. In contrast, the S6R-Y3 typically comes with a No. 0 bellhousing. Ensuring compatibility between the existing gear and the new engine can be tricky, especially when the exact bellhousing size on the existing engine is difficult to determine.

Laborde Products offers a comprehensive repower survey service, designed to identify and address potential challenges before they become costly issues. During this survey, they pay close attention to critical aspects like bellhousing compatibility. It’s not uncommon for the original bellhousing to be incompatible with a new Mitsubishi engine, necessitating the use of adapters or replacing the gear. To prevent any surprises, Laborde Products takes detailed measurements and consults with gear manufacturers, ensuring a smooth and seamless repower process.

The advantage of replacing the original setup allows you to tailor your powertrain for optimal performance. Investing in the correct bellhousing setup ensures that the engine and gear work seamlessly together, maximizing the efficiency and life of your vessel’s propulsion system. Over time, this careful customization can lead to significant savings in both maintenance and fuel costs, making the preliminary effort well worth it.

Optimizing Gear Ratios for the Increased Power of Mitsubishi S6R-Y3

While the C18 and S6R both operate at 1800 RPM, the increased horsepower of the Mitsubishi engine (684 HP versus the CAT’s 600 HP) can introduce gear ratio challenges. Most of these Caterpillar Marine engines are paired with a Twin Disc 5222 gear, which is also commonly used with the Tier 3 S6R. However, the increased power of the Mitsubishi engine may push the limits of the existing gear, requiring careful evaluation.

Operators may need to adjust the gear ratio to optimize performance and prevent mechanical issues. If the existing gear cannot handle the increased horsepower, a new gear may be required. Often, the gearbox may also be nearing the end of its service life, making the need for a replacement gear part of the overall repower strategy. In such cases, changing the gearbox is not just an adjustment but a necessary upgrade, which simplifies the process and ensures that both the engine and gearbox function optimally together.

Operators who have made these adjustments report that the improved efficiency and power output of the Mitsubishi engine. The result is a smoother, more responsive vessel that operates at peak efficiency, reducing wear and tear on the engine and extending its service life. This ultimately leads to lower lifecycle costs and less downtime, allowing your vessel to stay at work longer.

Engine and Parts Availability: Comparing CAT C18 and Mitsubishi S6R-Y3

When considering a repower from the Caterpillar C18 to the Mitsubishi S6R, engine and parts availability can play a significant role in the decision-making process. Based on reports from Laborde Products’ customers, the availability of these engines is notably limited, with factory delivery times extending over a year. For operators facing engine failure without spare units in stock, this can mean extended downtime, as new engines are either unavailable or come with long lead times. While third-party companies may offer rebuilt engines, these options are not widely available and can be difficult to source.

In addition to the difficulty of acquiring a new engine, parts availability also poses a significant issue. Spare parts often require long lead times for delivery, making it essential for operators to plan their overhauls and routine maintenance well in advance—sometimes up to six months. Despite the existence of parts stores across the country, marine-specific parts for the C18 are not always readily available, which can lead to further delays and operational disruptions.

The CAT C18, while a reliable engine in its own right, tends to have a shorter operational lifespan, with many users reporting a service life of around 18,000 to 20,000 hours before major replacements are necessary. Its origins as a pleasure craft engine, even with continuous-duty commercial ratings, contribute to its limitations in more demanding commercial applications.

In contrast, the Mitsubishi engine offers greater robustness and longevity, often exceeding 30,000 hours of service before significant overhauls are required. Mitsubishi’s well-established parts distribution network further ensures that replacement parts are readily available, minimizing downtime and reducing maintenance-related disruptions. This factor alone can make the Mitsubishi propulsion engine a more attractive option for those seeking reliability and ease of maintenance in challenging operational environments.

Overcoming Repower Challenges for a Superior Engine

By addressing simple issues like exhaust piping, bellhousing compatibility, and gear ratio adjustments early in the repower process, you set the stage for a powertrain that will serve your vessel efficiently and reliably for years to come.

The real-world challenges of repowering with a Mitsubishi S6R are minor hurdles that pale in comparison to the long-term benefits. Operators who have made the switch consistently report that the durability, reliability, and lower lifecycle costs of the fully mechanical marine engine far outweigh any initial adjustments needed during installation.